KEDA 2-Component Epoxy Resin Structural Adhesive

PRODUCT DESCRIPTION

KEDA 2-Component Epoxy Resin Structural Adhesive is a high-performance, two-part adhesive engineered for use in building systems. It is specifically formulated for both exterior and interior stone panel installations, including stone facades, cladding, and curtain wall systems.

VALUES

- Outstanding Durability: This product is formulated with modified epoxy resin polymers, offering excellent age resistance and long-lasting performance.

- Enhanced Toughness: After curing, the adhesive exhibits remarkable hydrolysis resistance, damp proofing, and chemical resistance. It remains stable under extreme temperatures, with excellent weatherability from -30°C to 90°C.

- High Utilization Efficiency: With a high viscosity and over 95% utilization ratio, this adhesive offers superior resistance to ground movement, compression, stretching, and shock, making it ideal for demanding applications.

- Non-Corrosive and Safe: The adhesive is non-corrosive and safe for human contact. Any accidental spills can be easily cleaned with soap and water.

- Cost-Effective and Clean: Designed for a clean construction environment, this adhesive minimizes the need for additional materials like ashes and gravel, reducing both the complexity and cost of the installation process.

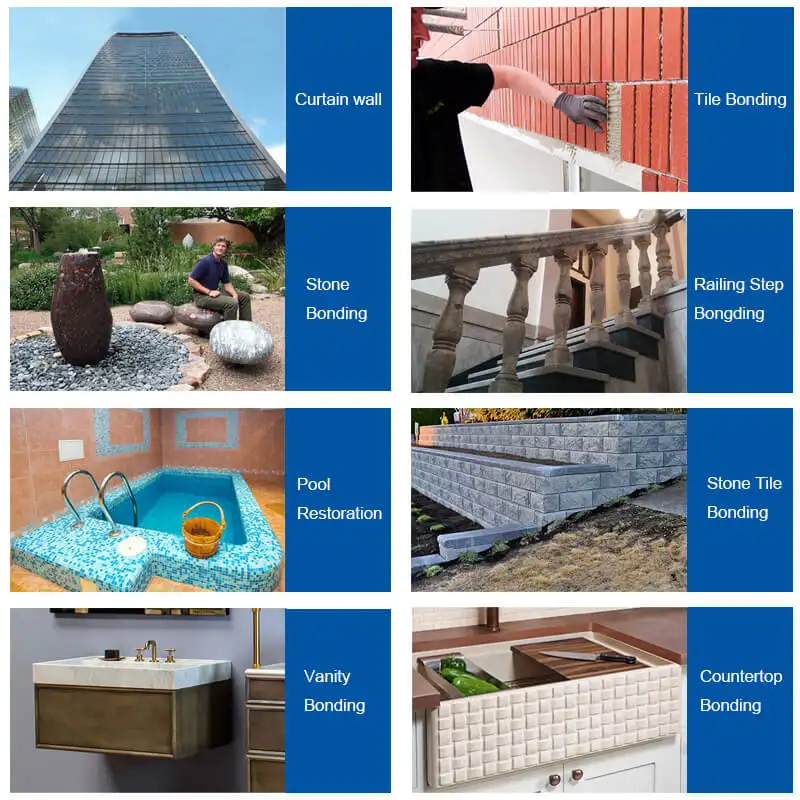

APPLICATION AREAS

- Stone Facade Installation: Ideal for securing stone panels and slabs on building exteriors.

- Indoor Stone Panel Installation: Perfect for installing stone panels on interior walls and surfaces.

- Curtain Wall Systems: Reliable for bonding materials in curtain wall installations, ensuring strong and secure attachment.

- Structural Reinforcement: Used to reinforce connections and joints within building structures, ensuring stability and strength.

- Architectural Cladding: Suitable for attaching various cladding materials to structural substrates in building systems.

ADHERES TO

- Natural Stone (e.g., granite, marble, limestone)

- Concrete

- Steel

- Aluminum

- Ceramics

- Composite Materialsvertine

PACKAGE

1L/Barrel, 2 Barrels/Set, 10 Sets/Box

5L/Barrel, 2 Barrels/Set, 2 Sets/Box

10L/Barrel, 2 Barrels/Set

USAGE INSTRUCTIONS

- Mixing Ratio: Ensure that the components from Stack A and Stack B are measured equally, as the quota of each stack must be identical for proper bonding.

- Mixing and Stirring: Mix the two components in equal parts, stirring thoroughly to ensure an even blend. Pay special attention to stirring from the bottom of the container to avoid any unmixed material. After mixing, the adhesive blend must be uniform, and the stone should be completely coated and ready for bonding.

- Timely Usage: The mixed adhesive must be used within the valid working time. Under no circumstances should the adhesive be applied after this time has elapsed. Keep in mind that higher temperatures will shorten the working time, while lower temperatures will extend it.

- Post-Application Handling: Once the adhesive is applied, the bonded parts must not be moved until the valid working time has passed. If any adjustments are necessary after this period, the adhesive must be remixed and applied again before proceeding with the bonding process.

- Curing: Allow the adhesive to cure according to the product instructions. Curing time varies with temperature and humidity, typically taking several hours to a full day.

- Final Inspection: After curing, inspect the bond for strength and integrity before putting the structure into service.

TECHNICAL INDICATORS

|

Variety of Product

|

PM slow dry style

|

PF quick dry style

|

|

Effective construction time

|

45 minutes

|

5 minutes

|

|

Primary dry time

|

12 hours

|

1 hours

|

|

Completely freezing time

|

4 days

|

6 hours

|

|

The Scope of the construct time

|

10~70℃

|

0~70℃

|

|

The character is stability after mixing

|

-30~90℃

|

-30~90℃

|

TIPS

- Minimum Adhesive Coverage: Ensure that the adhesive coverage for each stone piece is no less than 104 cm² per square meter, with a minimum adhesive layer thickness of 3 mm.

- Surface Preparation: The bonding surface must be dry, with a moisture content of no more than 15%, and free from dust, oil, and loose particles to ensure a strong bond.

- Surface Roughening: If the bonding surface is too smooth, it must be roughened to improve adhesion. Any materials or contaminants that could affect the bonding process must be thoroughly removed.

LIMITATIONS

- Safety: Wear gloves when using to avoid direct contact with skin.

- Cold Weather Construction: When working in temperatures below 10°C, use quick-drying adhesives specifically designed for low temperatures. The working time in these conditions is reduced to 5-6 minutes.

- Temperature Management: If the temperature at the bonding site falls below 5°C, the adhesive area can be gently heated, but the temperature should not exceed 65°C.

- Welding Precautions: Ensure that any welding work is performed at least 3 cm away from the bonded area to prevent damage to the adhesive bond.

- Reinforcement for Flawed Stones: For stone products that are loose or have numerous flaws, apply a layer of strong stone mending adhesive to the back of the stone to increase its rigidity and waterproofing.